In industrial engineering and manufacturing design, terms like Codes, Standards, and Specifications are frequently used. While they are closely related, each term carries its own distinct meaning, role, and purpose in practice. Understanding these differences ensures engineers and designers apply them correctly, promoting safety, quality, and efficiency in their work.

1. Codes – Mandatory Rules for Ensuring Safety

In engineering, Codes are not just guidelines but serve as the “backbone” of all projects involving design, construction, fabrication, installation, and operation. Developed by reputable organizations such as ASME (American Society of Mechanical Engineers) and ICC (International Code Council), Codes are often enforced by local or national authorities.

Unlike recommendations, Codes are legally binding requirements. Non-compliance with a Code can lead to project disapproval, legal liabilities, costly redesigns, and, most importantly, significant risks to human safety and the environment.

1.1. Codes in Practice: Mechanisms and Roles

Imagine a high-rise building located in an earthquake-prone area. It must be designed to withstand seismic forces. In such cases, Codes like the International Building Code (IBC) or Seismic Code provide specific guidelines on designing foundations, load-bearing structures, and selecting appropriate materials to ensure the building’s resilience during strong seismic events.

Each Code is established based on scientific data and extensive experimental studies. For example, the ASME Boiler and Pressure Vessel Code (BPVC), which governs the design and operation of pressure vessels and boilers, has been developed over decades of testing. This ensures that high-pressure equipment operates without the risk of explosion or leakage.

1.2. The critical role of Codes that cannot be ignored

- Ensuring Safety: This is the top priority. Codes set the minimum requirements for design and operation to protect people, assets, and the environment from potential risks.

- Enhancing Uniformity: When codes are widely applied, engineering structures and systems exhibit consistency in design and construction. This facilitates inspection, maintenance, and repair.

- Legal Protection: Engineers and contractors who comply with codes can avoid legal disputes stemming from incidents or safety violations.

In the oil and gas industry, pipeline systems for transporting oil and gas must comply with the ASME B31 code. This code specifies the minimum requirements for the design, materials, and inspection of pipeline systems. Failure to comply can lead to system leaks or explosions, potentially resulting in catastrophic disasters and significant losses in assets and lives.

1.3. Codes and Legal Implications

Unlike standards or specifications, codes have clear legal implications and violations can lead to penalties. For example, in the United States, a building not adhering to the International Building Code (IBC) may be suspended from operation or even ordered to be dismantled by authorities.

Codes are not merely dry sets of rules; they are tools for safeguarding communities, the environment, and the reputation of engineers. Engineers must always be well-versed in the codes relevant to their fields, as this is not only a mandatory requirement but also an ethical responsibility toward society.

In essence, codes are the foundation for all safe and efficient engineering projects. For engineers, adhering to codes is not only a legal obligation but also a commitment to ensuring quality and safety in their work. A code-compliant project not only provides peace of mind to investors but also strengthens public trust in the competence and professional ethics of the engineering team.

2. Standards – The compass for Consistency and Quality

In the fields of engineering and industry, standards serve as guidelines to establish uniformity and consistency across systems, products, and processes. Unlike codes, standards are not mandatory but voluntary; however, the value they bring is immense—from improving product quality to enhancing competitiveness in international markets.

2.1. What Are Standards?

Standards are sets of rules, guidelines, or technical specifications developed by professional organizations, engineering associations, or international bodies. Leading organizations like the International Organization for Standardization (ISO), the American National Standards Institute (ANSI), and the German Institute for Standardization (DIN) play key roles in the development and maintenance of these standards.

Standards are built based on consensus among industry experts and reflect the most advanced knowledge, technologies, and practices available at the time of publication. For example, ISO 9001, a standard for quality management systems, not only ensures product quality but also enhances the operational efficiency of organizations.

2.2. The key roles of Standards

Standards act as a bridge between theoretical ideas and practical implementation in production and operations. Below are the main roles of standards:

Ensuring Consistency:

Standards help products, services, and processes to be compatible, particularly in complex industries such as aerospace, construction, and automotive manufacturing. For instance, ISO 26000 on social responsibility enables organizations to adhere to common ethical principles in business operations, regardless of location.

Enhancing Quality and Efficiency:

Applying standards ensures that products and services meet a certain level of quality. This not only increases customer satisfaction but also optimizes production costs. For example, API 610 in the oil and gas industry specifies technical requirements for centrifugal pumps, ensuring high performance and durability in harsh environments.

Improving Safety:

Although not mandatory, many standards are developed to enhance safety levels in technical activities. ISO 45001, a standard for occupational health and safety management, is a prime example, helping businesses minimize risks related to workplace accidents and occupational diseases.

Facilitating International Trade:

International standards such as ISO and IEC (International Electrotechnical Commission) play a significant role in removing technical barriers between countries. When a product meets ISO standards, it is readily accepted in multiple markets worldwide, thus boosting exports and trade.

2.3. Standards in Practical Engineering and Industry

A clear example of the role of standards is found in the steel manufacturing industry. ASTM A36 defines basic requirements for strength, durability, and ductility of steel. This ensures that any batch of steel produced to ASTM A36 standards can be used for construction purposes without the need for retesting each batch.

Similarly, in pipeline manufacturing, the API 5L standard outlines regulations for materials, dimensions, and quality control processes. Adhering to this standard not only ensures pipeline integrity but also facilitates uniformity when assembling complex systems.

2.4. The relationship between Standards and Codes

An interesting point is that standards are often referenced as part of technical codes. For instance, the ASME Boiler and Pressure Vessel Code (BPVC) specifies that materials used in designing pressure boilers must comply with ASTM standards. This demonstrates that standards not only support practical implementation but also serve as the foundation for building regulatory codes.

2.5. Challenges in applying Standards

Despite the numerous benefits, applying standards is not always straightforward. Small businesses may struggle to access and implement international standards due to costs or a lack of technical expertise. Additionally, as technology advances at an accelerating pace, standards must be continuously updated to remain relevant, which can sometimes lead to delays or inconsistencies in application.

3. Specification – A detailed definition for each technical element

In engineering and industry, specifications serve as a detailed blueprint, outlining all necessary parameters, materials, and processes for design, manufacturing, or operation. Specifications ensure that all elements of a project align with technical requirements and expectations.

3.1. What is a specification?

A specification is a precise document detailing key aspects such as:

- Material Type: Materials must meet specific criteria for strength, corrosion resistance, or thermal durability.

- Equipment Specifications: Includes operating pressure, temperature, dimensions, or load capacity.

- Implementation Process: Specifies steps such as installation, testing, maintenance, or acceptance procedures.

Specifications are typically developed based on existing standards and codes. For example, designing a pressure pipeline may require materials that conform to ASTM A106 Grade B or higher, with clearly defined working pressures to ensure operational safety.

3.2. Role of specifications in Piping and Pressure Vessel industries

Ensuring Compatibility and Performance

In industrial piping systems, incorrect material selection or specifications can lead to operational failures. Accurate specifications ensure that all components, from pipes and flanges to valves, are compatible with the operating environment, such as corrosive fluids or high pressure.

Example: Specifications for a pipeline transporting corrosive chemicals like sulfuric acid may require materials such as Hastelloy C276 or stainless steel 316L, combined with a PTFE lining to protect against corrosion.

Optimizing Safety

For pressure vessels, specifications are critical to ensuring their ability to withstand high pressure and temperature. For instance, designing an LPG storage tank might specify materials like SA 516 Gr. 70, with detailed wall thickness calculations based on operating pressure, external loads, and ASME BPVC Section VIII standards.

Meeting Regulatory and Inspection Requirements

Specifications form the basis for inspection and approval by regulatory bodies like TUV or Lloyd’s Register. This is especially vital in the pressure industry, where even minor errors can result in catastrophic failures.

3.3. Challenges and importance of Specifications

Developing specifications demands deep technical expertise, particularly in balancing performance, cost, and safety. An unclear or inappropriate specification can lead to significant financial losses or pose risks to operators.

Thus, in every project, from industrial pipelines to pressure vessels, specifications are not just guidance documents but pivotal elements determining the success and sustainability of the system.

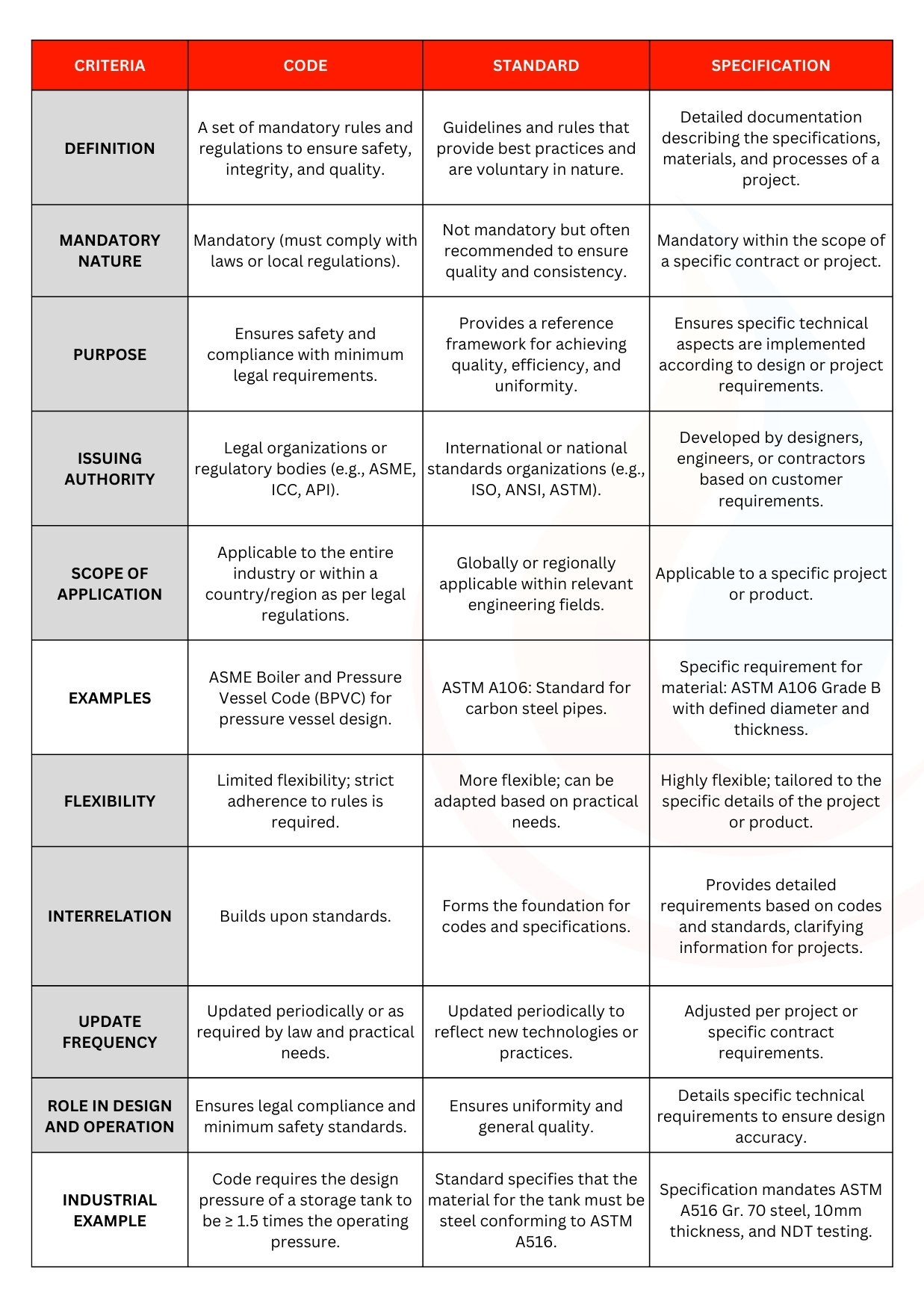

4. Comparison table of the differences between Code, Standard and Specification