Condensers are among the most critical components in thermal systems—especially in closed-loop cycles such as vapor-compression refrigeration, steam turbines, and various industrial processes involving working fluids in vapor phase.

1. Definition and operating principles of a condenser

1.1 What is a condenser?

A condenser is a type of heat exchanger used in thermal systems—including refrigeration units, steam turbine systems, boilers, and many industrial production lines. Its primary function is to convert a working fluid from its vapor phase to its liquid phase by rejecting heat to a cooling medium, such as water or air.

1.2 Operating principle of a condenser

From a thermodynamic standpoint, a condenser operates based on the fundamental principle that heat always flows from a region of higher temperature to one of lower temperature.

During the condensation process, the working fluid – after completing its heat transfer task (e.g., absorbing heat at the evaporator in a refrigeration system, or performing mechanical work in a steam turbine) – enters the condenser in a superheated vapor state, at high pressure and temperature. Inside the condenser, it transfers heat to a cooling medium, typically circulating chilled water or forced convection air.

The heat transfer process in a condenser involves two main stages:

- Desuperheating: This stage involves the removal of sensible heat, bringing the fluid down to its saturation temperature, converting the superheated vapor into saturated vapor.

- Condensation: This is the phase change from vapor to liquid, during which a large amount of latent heat of vaporization is released. This stage is the most critical in the condenser’s function, as latent heat transfer far exceeds that of sensible heat.

In some designs, the working fluid undergoes further cooling after complete condensation to form a subcooled liquid. This improves the overall thermal efficiency of the cycle and ensures more stable throttling in downstream components.

Though the operating principle may seem straightforward, the actual performance of a condenser depends on multiple operational and design factors, including:

– Condensing temperature and pressure: Higher condensing pressure results in higher saturation temperature, but also increases the compressor’s power consumption. In practice, a balance must be struck between energy efficiency and operational cost.

– Cooling medium temperature and flow rate: Lower cooling temperatures and sufficient flow rates enhance heat transfer performance. In the case of water-cooled systems, water quality (temperature, pH, hardness) significantly impacts efficiency and equipment longevity.

– Heat transfer efficiency across tube walls: Heat transfer surface design—including material selection, surface roughness, tube length, and geometry (straight tubes, helical coils, finned tubes)—is crucial. Fouling, scaling, and flow resistance can significantly degrade the overall heat transfer coefficient.

– Operational and maintenance conditions: Uncontrolled fouling or corrosion inside heat exchange tubes will deteriorate performance over time. In heavy-duty industrial systems, periodic inspection, chemical cleaning, and preventive maintenance are mandatory.

In industrial refrigeration systems or steam turbine setups, condensers are designed not only to recover energy efficiently but also to maintain the working fluid flow and stabilize the inlet pressure for downstream equipment such as pumps or expansion valves. Therefore, a condenser is not merely an auxiliary unit—it is a crucial control point that dictates overall system efficiency and long-term reliability.

When selecting or designing a condenser, engineers must consider more than just the refrigerant mass flow rate or nominal thermal load. A comprehensive assessment must include:

- The physical and thermodynamic properties of the working fluid

- Ambient operating conditions

- Variable thermal loads over the production cycle

- Ease of maintenance and cleaning

- Compliance with design codes and standards, such as ASME Section VIII, TEMA, or relevant TCVN standards.

2. Types and detailed construction of condensers

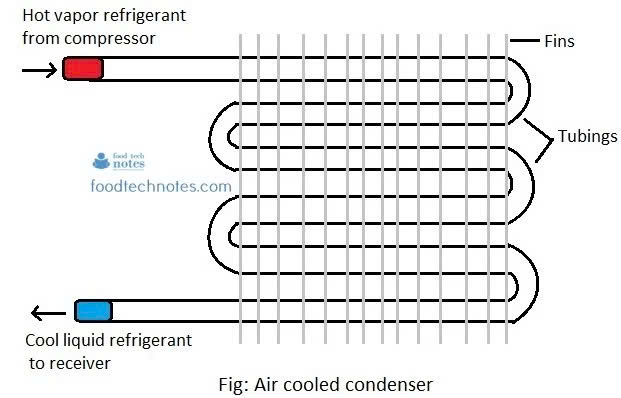

2.1. Air-cooled condenser

Construction:

This type of condenser typically consists of copper or aluminum tubes tightly bonded with aluminum or aluminum-alloy fins to increase the effective heat exchange surface area. One or more axial or centrifugal fans are arranged to force air across the finned coil, enabling convective heat transfer to the ambient environment.

Operating principle:

The high-pressure refrigerant vapor enters the condenser tubes and transfers heat to the surrounding air via forced convection. The air absorbs heat from the tube and fin surfaces, causing the refrigerant to condense into liquid. The entire process relies solely on ambient air as the heat sink medium.

Advantages:

- Simple and compact design; easy to manufacture and install.

- Eliminates the need for water cooling systems or cooling towers, reducing both initial capital investment and ongoing water-related operating costs.

- Low maintenance requirements, primarily focused on fan units and periodic cleaning of finned surfaces.

Disadvantages:

- Significantly lower heat transfer performance compared to water-cooled condensers, as air has a thermal conductivity 20–30 times lower than that of water.

- Highly dependent on ambient temperature: during hot weather, the overall system efficiency drops noticeably.

- Requires larger installation footprint, consumes considerable electrical energy for fans, and is susceptible to performance degradation due to dust accumulation if not regularly maintained.

Applications:

Air-cooled condensers are commonly used in residential and small-to-medium industrial refrigeration systems such as air conditioning units, packaged chillers, walk-in cold rooms, and in locations with limited water availability or where water discharge is not feasible.

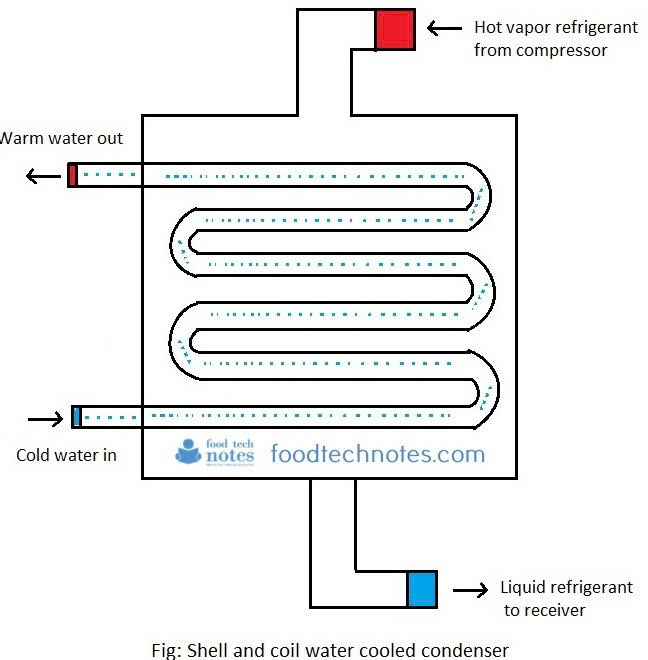

2.2. Water-cooled condenser

Construction & Types:

a) Double-tube/coaxial condenser

This type consists of two copper or steel tubes arranged in a straight or helical configuration, one nested inside the other. The refrigerant flows through the inner tube, while cooling water flows through the outer tube—or vice versa.

Advantages: Compact design, easy to manufacture, suitable for low-capacity systems.

Disadvantages: Difficult to clean; limited heat transfer efficiency due to small surface area.

b) Shell and tube condenser

This is the most widely used type in industrial applications. The refrigerant flows through the shell side, while cooling water circulates inside the internal heat exchange tubes. Baffles are installed to extend the water flow path and induce turbulence, which enhances heat transfer efficiency.

Advantages: Durable, easy to disassemble for maintenance, suitable for high-capacity systems.

Disadvantages: Large physical footprint; requires proper water treatment systems to prevent scaling and fouling.

c) Plate heat exchanger condenser

Constructed from a stack of corrugated metal plates pressed together to form alternating flow channels for refrigerant and cooling water.

Advantages: High heat transfer efficiency due to high flow velocities and turbulent flow; compact footprint.

Disadvantages: Susceptible to clogging if water is not adequately filtered; less durable than shell-and-tube designs; more difficult to clean and descale.

Cooling water continuously flows through the tubes or flow channels, absorbing heat from the condensing refrigerant and carrying it away. The water is typically recirculated and cooled via a cooling tower system.

Advantages:

- High heat transfer efficiency due to the superior thermal conductivity of water.

- More stable performance than air-cooled systems; less affected by ambient environmental conditions.

- More compact in design than air-cooled systems at equivalent capacities.

Disadvantages:

- Requires a complex water supply, filtration, and treatment system.

- Incur additional capital and operational costs for cooling towers, circulation pumps, and water treatment chemicals.

- Prone to corrosion and scaling, which can degrade performance and shorten equipment lifespan if not properly managed.

Applications:

Widely used in large-capacity industrial refrigeration systems, food processing plants, chillers, chemical factories, and power plants—especially where water is readily available and high thermal efficiency is required.

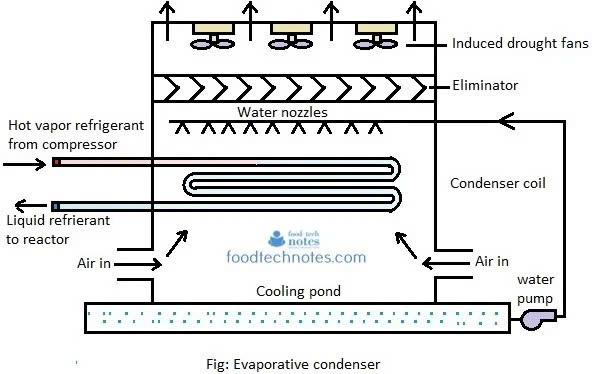

2.3. Evaporative-type condenser

Construction:

This condenser type combines the features of both water-cooled and air-cooled systems. It typically consists of:

- A heat exchange coil (carrying refrigerant inside);

- Forced-draft fan(s);

- A spray system that distributes water over the coil surface;

- A recirculating water basin;

- Drift eliminators to minimize water loss to the environment.

Operating principle:

Water is continuously sprayed onto the external surface of the heat exchange coils. As forced air flows over the wet coil surface, part of the water evaporates, absorbing latent heat from the refrigerant inside the tubes. This evaporative cooling effect significantly enhances heat rejection. The process combines convective air cooling and latent heat absorption through water evaporation.

Advantages:

- Delivers the highest thermal efficiency among the three main condenser types, thanks to the use of water’s latent heat of evaporation.

- More space- and energy-efficient than conventional water-cooled systems, as it eliminates the need for a separate cooling tower.

- Maintains stable operation even in harsh environmental conditions.

Disadvantages:

More complex in design and operation; requires regular control of water level, filtration, and periodic blowdown to remove contaminants.

Water losses due to continuous evaporation necessitate frequent replenishment; prone to scaling and corrosion, especially at high evaporation zones.

Demands strict and regular maintenance—neglecting this can lead to rapid performance degradation.

Applications:

Ideal for large-scale industrial cooling systems, such as power plants, petrochemical facilities, data centers, and cold storage warehouses with capacities ranging from tens to hundreds of refrigeration tons—where maximum efficiency and energy savings are critical.

3. Applications of condensers in industry

Condensers are essential components in numerous industrial sectors, playing a vital role in sustaining thermal cycles, enhancing energy efficiency, and maintaining process control. Depending on the operating environment, technical requirements, and industry-specific demands, each type of condenser offers distinct advantages.

3.1. Industrial refrigeration

Condensers are responsible for rejecting heat from the refrigerant after compression, thereby maintaining effective heat exchange throughout the refrigeration cycle. The choice of condenser type (air-cooled, water-cooled, or evaporative) depends on capacity scale and installation conditions.

Typical applications:

- HVAC systems for commercial centers, factories, and high-rise buildings.

- Cold storage for food preservation; deep-freezing warehouses for seafood or vaccines.

- Ice-making machines and chillers for process cooling.

3.2. Chemical and Petrochemical industry

Condensers assist in recovering high-value compounds from vapor streams while regulating pressure and temperature to ensure process stability. Plate condensers are often used in compact installations requiring high efficiency.

Typical applications:

- Vapor condensation in distillation columns (e.g., gasoline, oil, organic chemicals).

- Solvent recovery systems in the production of paints, plastics, and fine chemicals.

- Process cooling for heat exchangers and reactors.

3.3. Power generation (Power plants)

Typical application: In steam turbine cycles of thermal and nuclear power plants, condensers play a crucial role in condensing exhaust steam after the turbine.

Role of the condenser:

- Condenses exhaust steam to maintain vacuum at the turbine’s outlet, thereby improving Rankine cycle efficiency.

- Recovers and recycles condensate back to the boiler feedwater loop, ensuring a closed-cycle operation.

- These systems typically use large-scale shell-and-tube condensers, cooled by river or lake water, or a closed-loop cooling system.

In power plants, condensers are not only heat exchangers but also act as pressure control centers for the entire thermal cycle. Strict management of corrosion, scaling, and vacuum levels makes these systems significantly more complex and costly than in other industries.

3.4. Food and Beverage processing

Condensers ensure consistent low-temperature environments, which is critical for product quality and extending shelf life.

Typical applications:

- Rapid cooling systems for fresh milk, beer, and soft drinks.

- Freezing systems for seafood and processed meat.

- Industrial refrigerators and IQF (Individual Quick Freezing) production lines.

3.5. Pharmaceutical industry

Maintaining strict temperature and humidity control is vital in pharmaceutical production. In cleanrooms and drug manufacturing lines, condensers are essential parts of the environmental control system.

Typical applications:

- Precise temperature control for chemical reactions.

- Cold storage for medicines and vaccines in controlled warehouses.

- HVAC systems for cleanrooms and sterile processing areas.