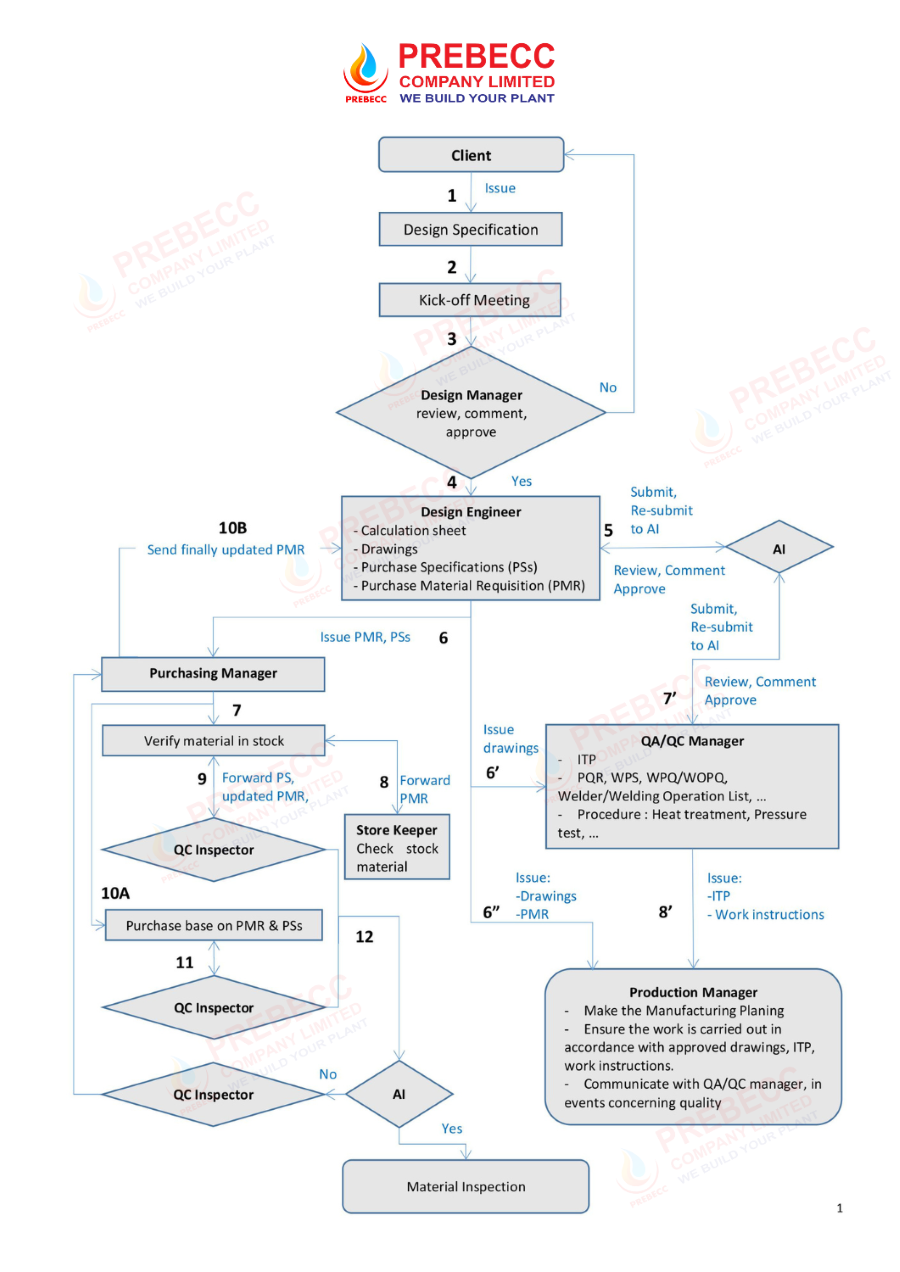

The ASME design and fabrication process ensures that pressure-retaining equipment such as boilers and pressure vessels meet stringent requirements in engineering, materials, and quality inspection. Below are the key steps in this process.

1. Defining design requirements

The ASME design process begins with a Design Specification provided by the client. This document defines key parameters such as operating conditions, design pressure, design temperature, service medium, and applicable codes (e.g., ASME Section I, Section VIII Div.1).

A Kick-off Meeting is then held with stakeholders, including the client, engineering, QA/QC, and the design team. The meeting aims to:

- Confirm the Scope of Work

- Clarify technical ambiguities in the specification

- Define inspection and acceptance criteria

- Align on project schedule and delivery plan

This stage ensures a clear foundation for design development and alignment with ASME code certification.

2. Design review and Technical documentation

After requirements are finalized, the engineering team prepares detailed design documents under close supervision by the Design Manager. This step includes two key phases:

2.1. Design review

The Design Manager reviews all technical parameters, selected materials, equipment configuration, and fabrication methods. The design must meet:

- Pressure integrity per ASME Code (allowable stress, corrosion allowance)

- Manufacturability and compatibility with inspection requirements

- Feasibility in terms of material sourcing, production, and NDT methods

2.2. Technical documentation

Once approved, the Design Engineer prepares the following documents:

- Calculation Sheet (wall thickness, stress, volume, etc.)

- General Arrangement & Detail Drawings

- Purchase Specification (PSs) for material standards and mechanical properties

- Purchase Material Requisition (PMR) with material grades per ASME standards

These documents are compiled and submitted to the Authorized Inspector (AI) for review and code compliance verification.

3. Approval by Authorized Inspector (AI)

After internal approval, the complete design package is submitted to an Authorized Inspector (AI) – a certified third-party inspector per ASME Code. This step ensures full compliance with the ASME Boiler and Pressure Vessel Code (BPVC).

Documents reviewed by AI typically include all technical submissions listed above.

The AI is responsible for:

- Verifying compliance with ASME Section I or Section VIII Div.1

- Reviewing material specifications, welding procedures, heat treatment, and NDT plans

- Requesting clarifications or revisions where necessary

Only after AI approval can the ASME Fabrication process and material procurement proceed. This step is critical for transparency and code integrity in all ASME Design in Vietnam projects.

4. Material procurement and preparation

Once the technical documents are approved by the Authorized Inspector (AI), the procurement team releases:

Purchase Material Requisition (PMR) – a list of required materials

Purchase Specifications (PSs) – detailed technical requirements for each material

4.1. Compliance with ASME material standards

All materials used for pressure-retaining equipment must comply with ASME Section II – Part A, B, C, or D, depending on type (plate, pipe, welding consumables, etc.). Commonly used material grades include:

- SA-516 Gr.70 – carbon steel for pressure vessels

- SA-106 Gr.B – seamless carbon steel pipe for high-temperature service

- SA-240 – stainless steel for special applications

If materials outside ASME listings are proposed, they must be supported by documentation from globally accepted sources such as:

- ASTM Standards

- EN Standards

- Manufacturer technical handbooks and data sheets

All materials, regardless of source, must be reviewed and approved by the AI before use in ASME Fabrication.

4.2. Material inspection and verification

The Store Keeper checks inventory against the PMR. If available, material samples are transferred to the QC Inspector for evaluation:

- Review of Mill Test Certificate (MTC) per EN 10204 3.1 or equivalent

- Visual inspection, material marking, and traceability verification

- Confirmation of compliance with approved specs – no substitution allowed

Only materials with confirmed origin and full traceability will be released for fabrication. New purchases are initiated only if stock materials are unavailable or non-compliant.

5. Fabrication oversight and Quality control

Once materials are verified and approved, the process moves to ASME fabrication, where precision and process control are crucial. The QA/QC Manager and Production Manager lead this phase.

5.1. Issuance and Compliance with Quality Control Documents

The QA/QC Manager issues the following mandatory documents:

- ITP (Inspection and Test Plan) – inspection checkpoints from cutting, welding, heat treatment to hydrostatic testing

- PQR (Procedure Qualification Record) – qualified welding procedures

- WPS (Welding Procedure Specification) – welding instructions for each joint

- WPQ/WQ/WPQOL – welder qualifications as per ASME Section IX

- NDE Procedures – for VT, PT, RT, UT, PWHT, leak tests, hydro and pneumatic tests

All documents must be approved before fabrication starts. These serve as the reference for AI hold/witness points during production.

5.2. Production planning and execution

The Production Manager, in coordination with QA/QC, prepares the fabrication schedule:

- All fabrication steps (cutting, forming, welding, assembling) must follow AI-approved drawings and WPS

- Execution follows the ITP sequence for proper inspections at hold and witness points

- Welders, NDT personnel, and operators must work per the WPS, monitored through daily logs

The Production Manager is also responsible for:

- Coordinating with AI during critical inspections (e.g., hydro test, final acceptance)

- Recording deviations and initiating corrective actions where needed

5.3. Role of QC Inspector

The QC Inspector conducts ongoing supervision throughout fabrication:

- Dimensional inspection based on approved drawings

- Visual inspection of welds

- Recording and reporting inspection results after each phase

- Submitting inspection records for AI review and confirmation

Any deviation from approved procedures must be addressed and revalidated by the AI before continuation.

Fabricating ASME-certified pressure equipment requires technical expertise, strict documentation, and seamless coordination. By adhering to approved ITPs, WPSs, and quality protocols, every unit is built for safety, performance, and full compliance with the ASME Code.