In every thermal system – from power plants and chemical processing lines to industrial boilers – the condenser coil plays a quiet yet decisive role in overall system efficiency.

It is at this stage that heat is rejected, vapor is condensed, and energy is recovered, enabling stable operation, reduced fuel consumption, and lower thermal emissions to the environment.

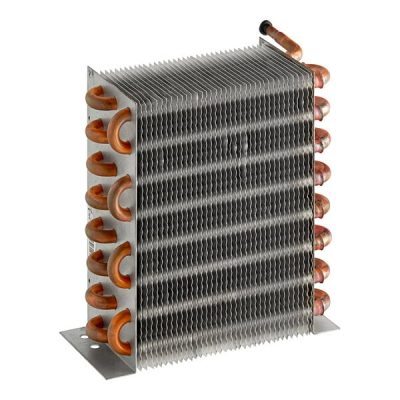

Condenser Coil

The condenser coil is one of the two main coils in a cooling system, completing the heat transfer cycle. It is typically installed outside the conditioned space and serves as the point where the refrigerant releases the heat absorbed from the system.

How Does a Condenser Coil Work?

The condenser coil is responsible for removing the energy collected by the evaporator coil. After absorbing heat, the refrigerant flows to the condenser coil, where heat is transferred to the surrounding medium — usually ambient air or cooling water.

As heat is rejected, the refrigerant undergoes a phase change from vapor to liquid. This heat rejection process enables the production of cooled air or cooled refrigerant, which is then circulated back through the HVAC system or industrial refrigeration system.

Condenser coils vary in size and configuration depending on the application. They are commonly housed in a metal casing with rows of tubes arranged vertically or horizontally. These tubes are fitted with finned aluminum surfaces to increase heat transfer area and improve thermal performance.

The Role of the Condenser Coil

If a condenser coil operates inefficiently or becomes obstructed, the entire system’s cooling capacity is compromised, making it difficult to maintain the desired temperature.

A properly functioning condenser coil improves energy efficiency by rejecting heat to the external environment instead of recirculating it back into the conditioned space.

In large-scale air conditioning and refrigeration systems, a larger or well-designed condenser coil enhances cooling capacity and contributes to a higher Seasonal Energy Efficiency Rating (SEER2).

Condenser Coil Maintenance

To maintain optimal performance, condenser coils must remain clean and free from airflow obstructions such as tall grass, debris, leaves, or dust buildup.

Over time, dirt accumulation on fins and tubes restricts airflow, forcing the system to operate under higher load and reduced efficiency. Regular inspection and cleaning are essential and should be performed by licensed or qualified technicians.

Condenser Coils in Boilers & Industrial Thermal Systems

In boiler systems and industrial thermal applications, the term condenser coil is used differently compared to HVAC systems.

In steam or superheated steam systems, a condenser may take the form of a shell-and-tube heat exchanger or coiled tubing, designed to condense steam into condensate for reuse or discharge.

When applied in boiler systems or waste heat recovery, condenser coils must withstand extreme conditions — high temperatures, high pressures, potential acid dew point condensation, and corrosive or fouling gas streams.

For example, C-PEX® pressurized heat exchanger coils are designed to operate at temperatures up to approximately 900 °C and pressures up to 150 bar, making them suitable for boiler flue gas and industrial process streams.

Design Considerations for Industrial Condenser Coils

Material selection, mechanical design, and maintenance strategy are critical. Key considerations include:

- Tube and header materials

- Fin configuration and surface treatment

- Fouling and corrosion resistance

- Cleaning systems

- Adequate cooling medium flow to prevent dry-out or thermal overload

In boiler flue gas systems containing water vapor or hot exhaust gases, condenser coils may be integrated into economizers, condensing economizers, or auxiliary condensers to recover latent heat and lower stack temperatures, thereby improving boiler efficiency.

*Important Terminology Note

Although the term “condenser coil” is often associated with cooling equipment, in industrial thermal systems it may function in a reverse role — recovering heat or condensing steam rather than rejecting heat.

Therefore, when writing or translating technical documentation, it is essential to clearly define whether the condenser coil is used for cooling or heat recovery/steam condensation, depending on the application context.