Accurate steel structure design from the outset helps to optimize costs, shorten construction time, and ensure load-bearing capacity under real-world conditions. To achieve these objectives, adherence to international design standards is a key factor. This article will introduce standards such as AISC 360, ASCE/SEI 7, CPR 305/EN 1090, and EN 1990 Eurocode, while also sharing Prebecc’s experience in applying these standards to real-world projects to deliver the highest quality to our clients.

1. Overview

Steel structures are now one of the most popular and widely preferred construction solutions in the building industry, particularly for large-scale projects such as factories, high-rise buildings, bridges, and other infrastructure works. Compared to traditional materials like concrete, wood, or brick, steel structures offer numerous advantages.

First, steel is lightweight. Despite its high load-bearing capacity, steel is much lighter than concrete or other construction materials. This reduces the load on the foundation, saving on construction costs and reducing the structural foundation requirements. Additionally, its lightweight nature makes transportation and installation easier and faster.

Second, steel is highly durable and strong. With its elasticity and flexibility, steel can withstand significant mechanical forces without permanent deformation. This is especially important for structures subject to dynamic loads such as bridges or buildings exposed to wind and earthquakes. Moreover, steel has excellent corrosion and oxidation resistance when properly treated, extending the lifespan of the structure.

Third, steel allows for quick and flexible construction. Steel components can be pre-fabricated in factories and transported to the construction site for assembly, significantly reducing construction time compared to traditional methods. This is particularly crucial for projects with tight schedules or those requiring a high degree of precision.

Finally, steel is flexible and highly recyclable. Steel can be reused multiple times without degrading in quality, which helps protect the environment and optimize resource use. Its flexibility also allows architects to be more creative in their designs, leading to unique structures that are both aesthetically pleasing and functional.

2. The importance of steel structure design standards

In any construction project, compliance with design standards is not only a legal requirement but also a critical factor in ensuring safety and quality. Particularly for steel structures, design standards play a vital role in accurately determining load-bearing capacities, minimizing the risk of structural failure, and ensuring stability and longevity.

Design standards such as AISC 360, ASCE, CPR 305/EN 1090, and EN 1990 Euro Code are developed based on rigorous scientific research, practical experience, and strict testing. These standards guide engineers in calculating, designing, and verifying steel structures. By adhering to these standards, engineers can ensure that steel components meet the necessary requirements for strength, durability, and resistance to various environmental conditions.

Compliance with design standards also protects the interests of investors and clients. When a project is designed and constructed according to established standards, users can trust in the quality and safety of the structure throughout its lifespan. This is especially crucial for industrial or commercial projects, where structural failure could lead to significant financial losses and safety hazards.

Furthermore, adhering to design standards enhances the reputation of contractors and design consultants. A project that meets recognized standards demonstrates professionalism and responsibility, creating long-term value for clients.

In conclusion, with its outstanding advantages in weight, strength, flexibility, and quick construction, steel structures have become a top choice for modern construction projects. Compliance with steel structure design standards not only ensures the safety and quality of a project but also contributes to environmental protection and cost optimization for investors.

3. Common steel structure design standards

3.1. AISC 360

AISC 360, also known as the Specification for Structural Steel Buildings, is the primary design standard for steel structures developed by the American Institute of Steel Construction (AISC). Regularly updated to incorporate advancements in technology and research, AISC 360 provides detailed guidelines for the calculation and design of steel structures, ensuring safety and efficiency across a wide range of projects, from factories and bridges to high-rise buildings.

3.1.1. Scope of Application

AISC 360 covers a broad spectrum of design elements, including beams, columns, connections, and complete structural systems. This standard is applicable not only to buildings but also to bridges, infrastructure, and large industrial structures. The requirements outlined in AISC 360 address structures subjected to both static and dynamic loads, as well as environmental factors such as wind and earthquakes.

3.1.2. Key Design and Calculation Requirements

AISC 360 defines two primary methods for steel structure design:

- LRFD (Load and Resistance Factor Design): This method uses higher load factors and reduces resistance factors to calculate maximum load-bearing capacity under hazardous conditions.

- ASD (Allowable Strength Design): Focuses on operational load conditions, reducing costs while ensuring safety under normal loads.

The standard also provides specific guidance on calculations related to tensile, compressive, bending, and torsional stresses in steel components, ensuring the stability of the entire structural system. Additionally, it includes stringent regulations on welding, bolting, and the connections between structural elements.

3.2. ASCE (American Society of Civil Engineers) Standard Overview

3.3. CPR 305/EN 1090

CPR 305/EN 1090 is a European Union standard regulating the manufacturing and installation of steel and aluminum structures. CPR 305 refers to the Construction Products Regulation (CPR), while EN 1090 is the specific standard governing quality certification for steel structural products entering the European market.

3.3.1. Scope of Application

EN 1090 provides detailed requirements for the entire process from manufacturing, assembly, to quality inspection of steel components. The scope of the standard includes structural components used in civil, commercial, industrial buildings, and infrastructure projects such as bridges, factories, and high-rise structures.

3.3.2. Key Requirements for Production and Quality Control

EN 1090 mandates strict control over every steel product from production to installation. This includes certification of welding processes, use of compliant materials, and ensuring precision in manufacturing. A significant element of EN 1090 is CE Marking, which certifies that products meet the necessary standards to be traded in the European market.

The standard ensures that only high-quality and safe products are implemented in construction, minimizing risk and maintaining uniformity across the industry in Europe.

3.4. EN 1990 Eurocode

EN 1990 is the general Eurocode standard outlining the basic principles and requirements for structural design, including steel structures. Recognized across Europe and many other countries, Eurocode provides a legal and technical framework for the efficient and safe calculation of structural elements.

3.4.1. Scope of Application

EN 1990 applies to all types of structural projects, from civil to industrial constructions. This standard covers the general principles for different materials, with steel being a crucial component. It provides specific guidelines for stress, load-bearing, and structural modeling, ensuring consistency and safety across various construction types.

3.4.2. Key Design and Calculation Requirements

Eurocode employs a calculation methodology based on safety factors, where risk tolerance and material strength are integrated into the design load requirements. EN 1990 requires engineers to account for dynamic factors like earthquakes and wind loads, in addition to long-term load-bearing capacity and structural stability of steel components.

The standard ensures that all designs are not only resilient under typical loads but also capable of handling extreme conditions, contributing to the long-term durability and safety of constructions in various environments.

4. Comparison and evaluation of steel structure design standards

Understanding steel structure design standards such as AISC 360, ASCE/SEI 7, CPR 305/EN 1090, and EN 1990 Eurocode is a crucial factor in ensuring the safety, efficiency, and sustainability of construction projects. Each standard carries unique methods and application scopes, optimized for different types of projects and specific technical conditions.

4.1. Similarities and Differences

4.1.1. Calculation Methods

- AISC 360: This standard uses two main methods: LRFD (Load and Resistance Factor Design) and ASD (Allowable Strength Design). LRFD employs higher load factors to ensure maximum safety under extreme load conditions, while ASD focuses more on everyday operational conditions with a lower safety margin.

- ASCE/SEI 7: Primarily focuses on dynamic load calculations, such as wind, seismic, and snow loads. The calculation methods in ASCE are often based on ground acceleration, load distribution, and climatic factors like hurricanes.

- CPR 305/EN 1090: This standard does not emphasize load calculations but rather focuses on production processes, material quality, and quality control during the fabrication and assembly of steel structures. Load-related calculations are supplemental to this standard.

- EN 1990 Eurocode: Eurocode provides a detailed method for structural system calculations, combining load analysis and material stress computations. EN 1990 mainly uses higher safety factors to account for severe real-world conditions such as earthquakes and strong winds.

4.1.2. Design Loads

- AISC 360 and ASCE/SEI 7: Both standards have specific provisions for static and dynamic loads. AISC focuses more on gravity loads and wind loads in high-rise building design, while ASCE 7 emphasizes seismic and high wind loads, especially in geographical regions prone to natural disasters.

- CPR 305/EN 1090: This standard does not provide detailed design load specifications. Instead, it emphasizes the durability of steel materials during production and construction.

- EN 1990 Eurocode: Eurocode offers guidance on gravity loads, wind loads, seismic loads, and climatic factors such as temperature, ensuring that the structure can withstand harsh weather conditions and natural disasters.

4.1.3. Material Requirements

- AISC 360: Provides strict regulations on the types of steel used in structural applications, including requirements for tensile strength, ductility, and temperature resistance. AISC also guides the selection of welds and bolts to ensure proper connections between structural components.

- ASCE: ASCE does not clearly define material requirements but focuses on load and force impact. The materials used in calculations must comply with other standards like AISC or ASTM.

- CPR 305/EN 1090: EN 1090 clearly outlines quality certification for materials, particularly regarding control over the production process, ensuring that each steel structure product meets standards before installation. CE Marking is an integral part of this standard, certifying that steel products meet quality requirements for circulation in the European market.

- EN 1990 Eurocode: Eurocode requires materials to meet specific technical standards, particularly regarding resistance to environmental factors and material longevity. This means the chosen materials must not only meet load-bearing requirements but also be durable under harsh environmental conditions.

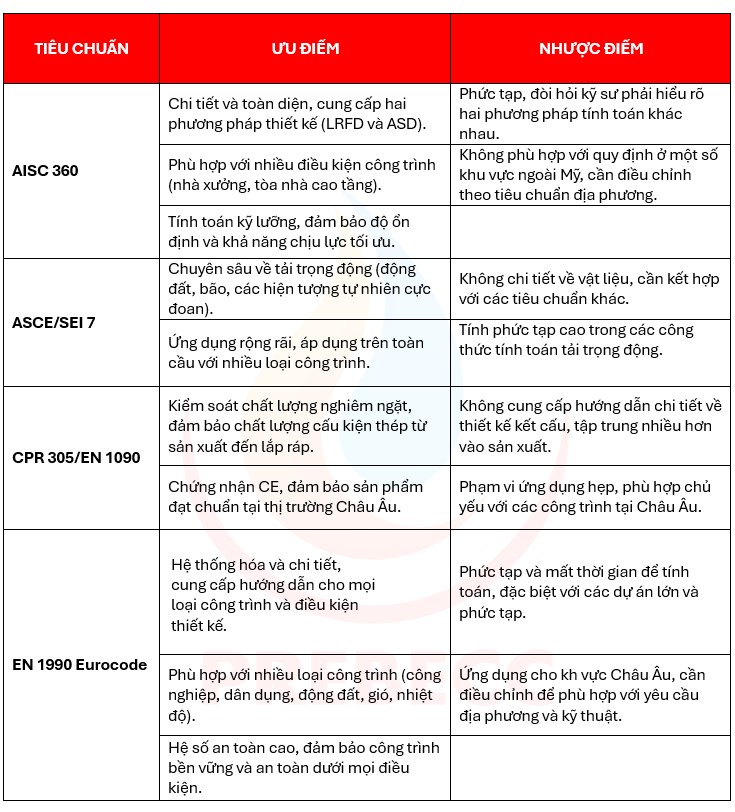

4.2. Advantages and Disadvantages of each steel structure design standard

The following table compares the advantages and disadvantages of each standard, making it easier to choose the appropriate one for specific projects:

5. PREBECC Professional steel structure design services

5.1. Design Process

Prebecc follows a stringent design process to ensure that steel structure projects are executed according to standards and meet the rigorous requirements of clients. Instead of directly manufacturing and installing, we focus on supporting clients with detailed technical documentation to facilitate smooth fabrication and assembly.

The process includes the following steps:

Project Requirement Analysis: Prebecc’s engineering team surveys and analyzes the requirements of each project, identifying factors such as loads, environmental conditions, and design objectives. Based on this, we select the appropriate design standard for the project, such as AISC 360, ASCE, CPR 305/EN 1090, or EN 1990 Eurocode.

Detailed Design: Using specialized software, we perform detailed design according to the selected standard, from load calculations to structural simulations. Comprehensive technical drawings are provided to support the production and quality inspection phases.

Verification and Handover: After completing the design, Prebecc conducts thorough checks on safety and quality factors in accordance with international standards. Detailed technical documentation will be handed over to the client for use during fabrication and assembly.

5.2. Technology and Software

Prebecc employs advanced technologies and software to ensure accurate and efficient designs:

- AutoCAD, Tekla Structures: For creating detailed drawings and 3D models, making it easy to visualize the steel structure and ensuring feasibility in production.

- SAP2000: For structural analysis, allowing us to evaluate loads and optimize designs based on international standards.

- Advanced Steel, Revit: To integrate structural design with BIM (Building Information Modeling) systems, enabling comprehensive information management from the design phase to project completion.

By utilizing these modern tools, Prebecc can design and implement complex steel structure projects with high accuracy and efficiency, ensuring that the constructions not only meet but exceed technical and safety requirements.

5.3. Engineering Team

A core factor in Prebecc’s success is its team of experienced and highly skilled engineers. With years of experience in the steel structure field, Prebecc’s engineers are not only proficient in international standards like AISC 360, CPR 305/EN 1090, and Eurocode but also possess the ability to apply them creatively and flexibly in each project.

- Diverse Expertise: Our engineering team has experience working with various types of projects, ranging from industrial plants to infrastructure works.

- Certifications and Training: Engineers at Prebecc hold professional certifications and regularly participate in advanced training courses on design standards and the latest technologies in the steel structure industry.

- Innovative Spirit: Besides adhering to technical standards, our engineers continuously seek optimal solutions to deliver the best value to clients, from minimizing production costs and enhancing aesthetics to ensuring maximum safety for the structures.