In engineering design and structural construction, allowable stress is an indispensable concept that ensures the safety and durability of structures. It represents the maximum stress a material or structure can withstand under normal working conditions without experiencing critical failure. This article delves into the definition, applications, and measures to maintain stress levels within allowable limits.

1. What is allowable stress?

1.1. What is Stress?

In the field of material mechanics, stress refers to the measure of force acting on a unit area within a material. It is a critical parameter for evaluating the load-bearing capacity of an object subjected to external forces.

Technically, stress is defined as the ratio of the applied force (F) to the cross-sectional area (A) over which the force is distributed, expressed using the formula:

σ = F/A

Where:

- σ: Stress (in Pascal, Pa).

- F: Applied force (in Newtons, N).

- A: Cross-sectional area (in square meters, m²).

In the International System of Units (SI), stress is measured in Pascals (Pa), where 1 Pa = 1 N/m².

1.2. What are Fabricated/Constructed Structures?

A structure is a system of interconnected components designed to withstand loads and distribute stresses efficiently. In industrial manufacturing, structures play a vital role in ensuring the stability and safety of facilities or equipment.

Common Types of Structures:

- Concrete structures: Primarily used in construction, offering excellent compressive strength but limited tensile capacity.

- Steel structures: Widely employed in industrial applications due to their high load-bearing capacity, durability, and resistance to bending and torsion.

- Wooden structures: Though less common in heavy industries, wood is lightweight and easy to process, making it suitable for smaller projects.

Factors Affecting Structural Load Capacity:

- Material type: Different materials have unique stress limits. Steel, for instance, excels in tensile and compressive strength compared to concrete or wood.

- Geometric design: The shape and size of a structure significantly influence how stress is distributed.

- Load characteristics: The type (static or dynamic), direction, and intensity of the applied load must be carefully considered.

- Environmental factors: Temperature, humidity, and chemical exposure can degrade structural integrity over time.

1.3. Allowable Stress

Allowable stress is the maximum stress a material or structure can safely endure under normal operating conditions without exceeding its elastic limit or causing failure.

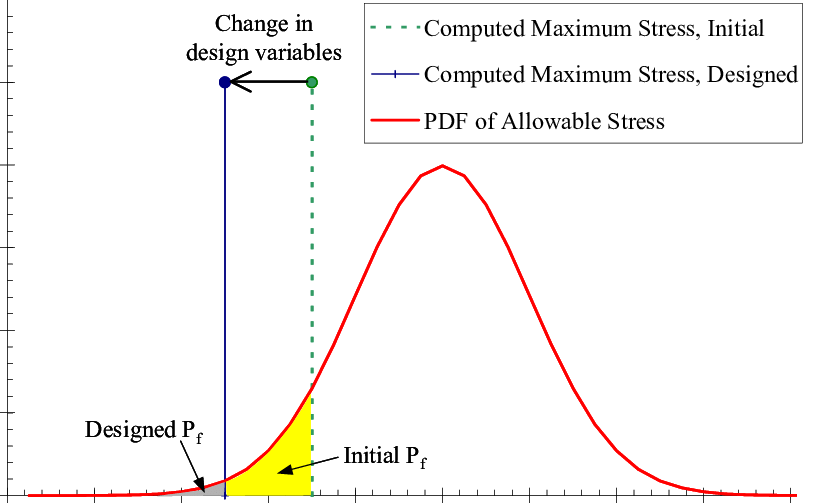

This value is derived from the material’s yield stress or ultimate stress, divided by a safety factor (n), which accounts for uncertainties in design, environmental conditions, and the consequences of failure.

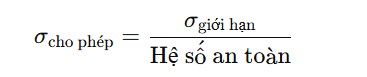

The formula for allowable stress is:

Where:

- σₐ: Allowable stress.

- σₗ: Stress limit of the material (yield or ultimate stress).

- Safety factor (n): typically ranging from 1.5 to 3, depending on design standards.

For example, in steel bridge design, allowable stress is carefully regulated to ensure that the structure remains safe even under exceptional load conditions. Similarly, in industrial applications such as pressure vessels or cranes, controlling allowable stress is critical to preventing catastrophic failures.

Differences between actual stress and allowable stress

- Actual Stress: The stress experienced by a structure under actual load conditions.

- Allowable Stress: The safety threshold, calculated to ensure the structure remains within safe operating limits and avoids dangerous states or failure.

If actual stress exceeds allowable stress, the structure risks instability or damage. Therefore, assessing and comparing these two values is a critical step in designing and operating industrial equipment.

The Significance of the Safety Factor

The safety factor is not merely a buffer but also a measure of design stability. An appropriate safety factor serves to:

- Compensate for calculation or construction inaccuracies.

- Provide a margin for unexpected loads or extreme operating conditions.

- Extend the lifespan of the structure and ensure long-term performance.

2. Importance of Allowable Stress

Allowable stress is not just a calculated value; it is a key determinant of a structure’s safety and longevity. When stress levels within a structure exceed the allowable limit, the risks of failure, such as plastic deformation, cracking, or total collapse, significantly increase.

Protecting Human Safety and Assets

Limiting stress ensures that structures remain intact, reducing the likelihood of accidents and property damage.

Optimizing Design Costs

By maintaining stress levels within safe limits, materials can be selected and utilized more efficiently, avoiding both overloading and unnecessary excess.

Extending Structural Lifespan

Controlling stress within allowable limits minimizes risks of failure due to deformation or material fatigue, thereby enhancing durability and service life.

3. Factors influencing Allowable Stress levels

The allowable stress level of a material or structure is affected by various factors, including material properties, structural type, and operating conditions. Understanding these factors ensures safe and efficient design while extending the equipment’s service life.

3.1. Material properties

The mechanical properties of a material determine its ability to bear force and stress. Key parameters include:

- Elastic Limit: The maximum stress a material can withstand and still return to its original state once the applied force is removed.

- Yield Strength: The stress level at which a material begins to deform plastically, losing its ability to return to its original shape.

- Ultimate Strength: The maximum stress a material can endure before failure.

Additionally, environmental factors such as humidity, temperature, and chemical agents can affect material properties. For example:

- High temperatures can reduce the elastic limit and tensile strength of steel.

- Humidity and corrosive environments (such as marine conditions) can degrade a material’s mechanical properties over time.

3.2. Structural type

The type and shape of a structure play a vital role in load distribution and stress endurance.

- Statically Determinate Structures: These are structures where the number of equilibrium equations equals the number of unknowns. They are straightforward to calculate and offer easier stress control.

- Indeterminate Structures: These have more unknowns than equilibrium equations, requiring more complex analyses to evaluate stress.

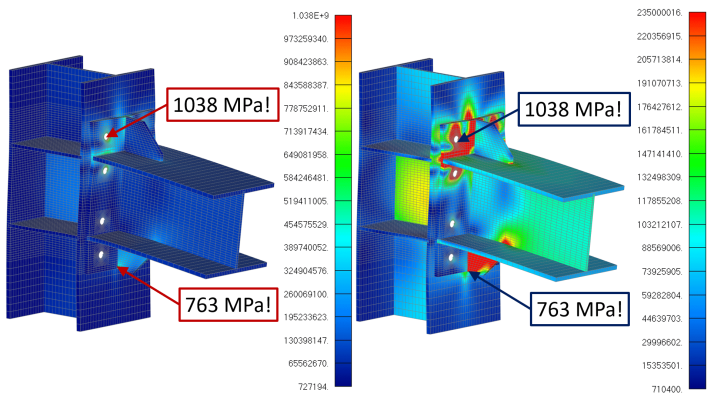

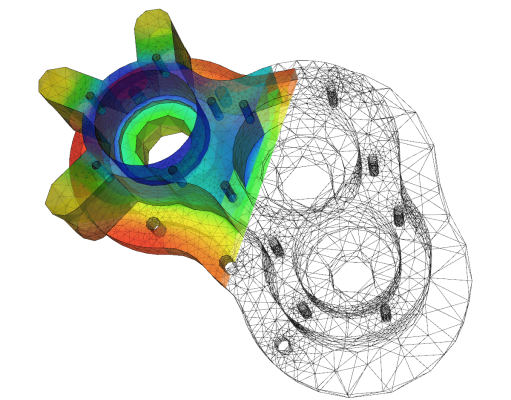

The cross-sectional shape also significantly impacts allowable stress levels. Cross-sections like I-beams, H-beams, or circular tubes are commonly used to optimize load-bearing capacity. Additionally, the connection method (e.g., welding, bolting, or riveting) determines how stress is distributed within the structure.

3.3. Operating conditions

Stress is influenced by the type of load the structure bears:

- Static Load: A load that remains constant over time.

- Dynamic Load: A load that varies continuously, causing stress fluctuations and potentially leading to material fatigue.

- Thermal Load: Temperature changes can induce thermal stress due to material expansion or contraction.

Moreover, long-term operation in harsh environments leads to durability reduction, such as material fatigue or corrosion. These conditions must be carefully considered when calculating allowable stress levels.

4. Measures to ensure stress remains within Allowable Limits

To ensure that stress levels in a structure do not exceed allowable limits, several essential methods should be implemented.

First, designing and selecting suitable materials are fundamental. Structures must be designed to withstand the maximum expected load, including both static and dynamic loads. The materials should meet technical standards, such as tensile strength, corrosion resistance, and stability under high-temperature or high-pressure conditions.

Source: https://www.researchgate.net

Furthermore, periodic inspection and maintenance play a crucial role in maintaining structural safety. Regular inspections allow for early detection of signs of stress concentration, deformation, or potential failure. For instance, in steel structures, examining welds or bends is often critical for identifying potential risks.

Effective load management is also a key factor. Limiting the applied load or distributing it evenly across the entire structure minimizes the risk of stress concentration. For equipment like cranes or storage tanks, automated monitoring systems can continuously track loads to ensure that the structure does not exceed its design limits.

Additionally, testing the structure before it is put into operation is an essential measure. Methods such as real load testing or simulation analysis using Finite Element Analysis (FEA) help identify stress levels under actual working conditions. This enables the implementation of necessary adjustments to ensure safety and performance.