Technical design plays a critical role in ensuring the quality, safety, and operational efficiency of industrial equipment. Adhering to international standards such as API and ASME is essential for achieving the highest levels of reliability in projects. However, each standard has its unique strengths, tailored to specific industries and requirements. Let’s explore the differences between these two standards to help you choose the optimal design solution for your business.

1. Introduction to API and ASME Standards

In the realm of technical design, compliance with international standards not only ensures product quality but also enhances safety and operational efficiency. Among these, the API (American Petroleum Institute) and ASME (American Society of Mechanical Engineers) standards are two of the most widely recognized frameworks, applied across various industrial sectors globally.

- API Standards: Developed by the American Petroleum Institute, these standards primarily focus on the oil and gas sector, covering the production, operation, and maintenance of equipment specific to this industry.

- ASME Standards: Created by the American Society of Mechanical Engineers, these standards emphasize the design and fabrication of pressure vessels, boilers, pipelines, and structures subjected to high pressure.

While both standards aim to ensure safety and technical efficiency, they are tailored to meet the distinct needs of different industrial applications.

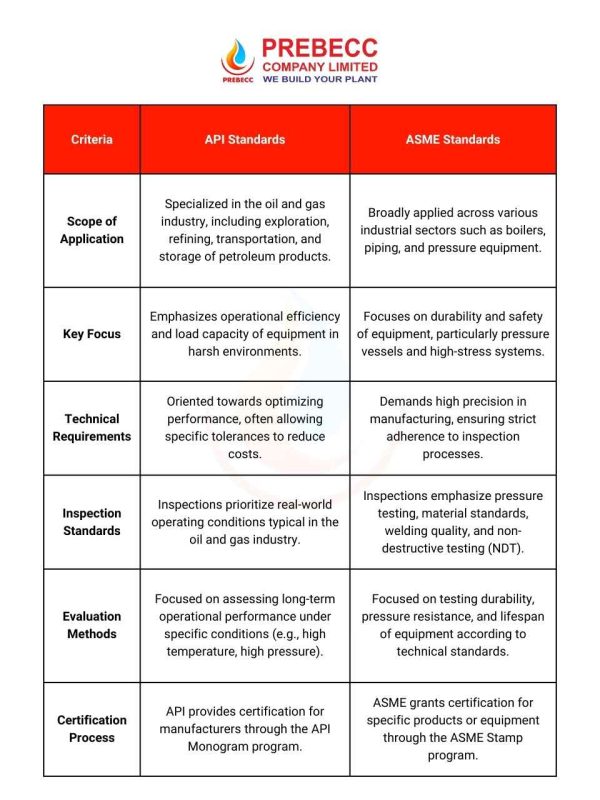

2. Detailed Comparison Between API and ASME Standards

2.1. Scope of Application

The API standards are specifically crafted for the oil and gas industry, focusing on designing and operating equipment in high-risk environments such as offshore oil extraction or crude oil storage. On the other hand, ASME standards have a broader scope, applying to multiple industries, including energy, chemical processing, food production, and water treatment.

Example:

- A storage tank in the oil and gas industry must comply with API standards to ensure its ability to withstand pressure and temperature in extreme conditions.

- Meanwhile, a heat exchanger in a chemical plant might adhere to ASME standards to guarantee pressure safety and mechanical integrity.

2.2. Key Focus in Technical Design

- API: Prioritizes equipment performance. These standards allow certain technical tolerances to reduce costs while maintaining safety requirements. API standards also aim to optimize design to enhance operational capabilities under real-world conditions.

- ASME: Focuses on sustainability and safety. ASME standards require strict adherence to technical rules in design and manufacturing, permitting minimal tolerances, especially for high-pressure equipment.

2.3. Inspection and Certification Processes

API standards focus on performance-based evaluations to ensure long-term operational reliability in harsh oil and gas environments, while ASME standards emphasize rigorous non-destructive testing (NDT) methods, such as ultrasonic testing and radiography, to verify mechanical integrity and structural soundness.

2.4. Practical Applications

- API Standards: Cater specifically to the technical requirements of the oil and gas industry, covering the production, operation, and maintenance of equipment like storage tanks, pipelines, and extraction systems. API regulations are designed to withstand the extreme conditions typical of the oil and gas sector, such as high pressure, extreme temperatures, and corrosive environments.

- ASME Standards: Primarily focus on pressure vessels, boilers, and piping systems across various industries. ASME standards establish stringent rules regarding design, materials, and inspection processes to ensure maximum safety and durability, regardless of the application domain.

3. Technical Design Services Following API and ASME Standards at Prebecc

With a team of experienced engineers and state-of-the-art facilities, Prebecc delivers professional technical design services adhering to API and ASME standards, ensuring the highest customer satisfaction.

3.1. Technical design services based on API Standards

Prebecc specializes in designing equipment for the oil and gas industry, ranging from crude oil storage tanks to gas pipeline systems. We are committed to using high-quality materials and optimizing designs to ensure operational performance under the harshest conditions.

3.2. Technical design services based on ASME Standards

For heavy industries like energy and chemical manufacturing, Prebecc provides designs for pressure equipment, boilers, and piping systems in compliance with strict technical regulations. Non-destructive testing (NDT) processes are integrated into every stage to ensure durability and equipment safety.

WHY CHOOSE PREBECC?

- Practical Experience: Over six years of delivering industrial projects in heavy engineering sectors.

- Commitment to Quality: Full compliance with international standards for customer peace of mind.

- Comprehensive Support: Assisting clients through design, production, inspection, and maintenance phases.