In Q4/2025, PREBECC continued to demonstrate its engineering and fabrication capability by completing a project supplying three vertical Air Receivers, designed and manufactured in full compliance with ASME Section VIII, Division 1 – 2025 Edition, and certified by Lloyd’s Register Quality Assurance (LRQA).

1. Technical Specifications

- Quantity: 03 units

- Type: Vertical Air Receiver (Pressure Vessel)

- Dimensions: OD 762 mm × SL 1600 mm × Thickness 10 mm

- Material: SA-516 Gr.70 carbon steel – a high-strength, pressure-rated material widely used for Pressure Vessel fabrication.

- Design Code: ASME Section VIII, Division 1 – 2025 Edition

- Inspection & Certification: Lloyd’s Register Quality Assurance (LRQA)

- The internal surface of each vessel is coated with an anti-corrosive epoxy lining to protect against moisture and condensate in compressed air service.

- The external surface is left unpainted to facilitate routine inspection and maintenance.

2. Design and Technical Approval Process

From the project’s initial stage, PREBECC’s engineering team carried out structural design, stress calculations, and load simulations in accordance with ASME Section VIII, Division 1 (2025 Edition).

All Strength Calculations and Fabrication Drawings were submitted to LRQA, an independent international inspection body, for review and approval prior to fabrication.

This rigorous process ensured full compliance with international safety and technical standards while reinforcing PREBECC’s internal Fabrication Quality Management System — a foundation for maintaining global manufacturing consistency and reliability.

3. Fabrication Process – Strict Quality Control

The fabrication of the Air Receiver and Pressure Vessel was carried out under the direct supervision of LRQA technical inspectors, strictly following the approved Inspection & Test Plan (ITP).

1. Incoming Material Inspection

All materials — including SA-516 Gr.70 steel plates, fittings, flanges, bolts, and welding consumables — were verified based on Mill Certificates and Visual Inspection before production.

Only materials that meet mechanical, chemical, and traceability requirements are accepted for use.

2. Welding Procedure Specification (WPS) Preparation

PREBECC developed and approved the Welding Procedure Specification (WPS) and Procedure Qualification Record (PQR) in accordance with ASME Section IX.

The WPS defines the qualified welding parameters and techniques to ensure consistent weld quality, mechanical integrity, and leak-tightness during fabrication.

It also serves as an essential technical document demonstrating the manufacturer’s welding capability during third-party inspections by LRQA, ABS, BV, or DNV.

All welders participating in the project underwent a Welder Qualification Test (WQT) and were authorized to work only upon passing.

PREBECC’s welding team holds 6G welding certificates, representing advanced proficiency in all welding positions and ensuring weld quality stability under all fabrication conditions.

3. Machining and Shell Welding

All components of the Pressure Vessel were precisely cut, rolled, and welded according to the approved procedures, with strict control over deformation, weld gaps, and interpass temperature.

Every welding operation was documented in the Fabrication Log to ensure full traceability and quality verification throughout the production process.

4. Non-Destructive Testing (NDT)

This is one of the most critical stages in the fabrication of Air Receivers and Pressure Vessels, confirming the welding integrity and workmanship quality of PREBECC.

All longitudinal seams and circumferential seams were subjected to 100% Radiographic Testing (RT) or Ultrasonic Testing (UT).

Advantages of NDT methods:

- Detect internal weld defects such as porosity, cracks, or slag inclusions — invisible to the naked eye.

- Maintain material integrity, ensuring the vessel’s structural soundness.

- Verify leak-tightness and pressure resistance of the vessel before commissioning.

- All NDT results were reviewed, cross-checked, and certified by LRQA, ensuring full transparency and reliability of the entire fabrication process.

5. Hydrostatic Test

After successful completion of NDT, each Air Receiver underwent a hydrostatic pressure test at 1.3 times the design pressure.

This test confirms the vessel’s pressure resistance, leak-tightness, and elastic deformation limits, ensuring full compliance with ASME Section VIII, Division 1 requirements. The entire process was witnessed and verified by LRQA inspectors to guarantee integrity and reliability.

6. Coating & Final Finishing

Following the pressure test, the internal surface of each vessel was cleaned and coated with a corrosion-resistant epoxy paint, specifically designed for high-pressure and high-humidity environments.

The external surface was left as bare metal, allowing the end user to apply their own coating system if required — a practical approach that simplifies inspection and future maintenance.

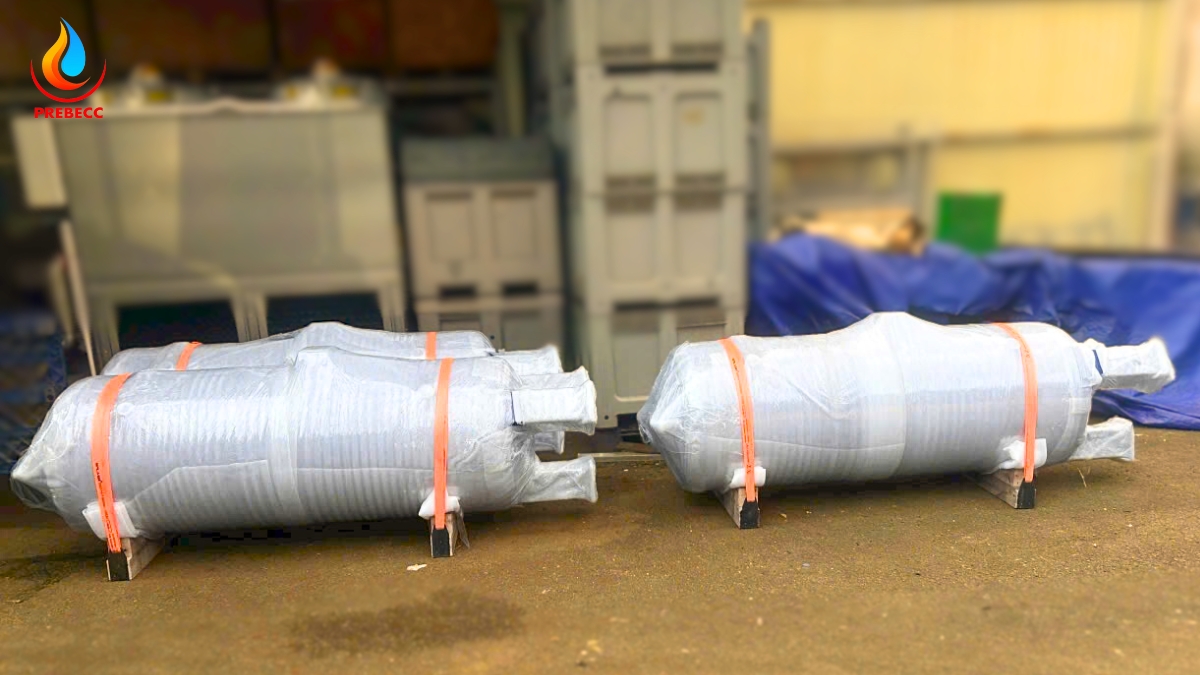

4. Certification & Delivery

Upon completion of fabrication, inspection, and testing, LRQA carried out the Final Inspection to verify overall compliance.

Only after confirming that all technical requirements, documentation, and test results fully met the ASME Section VIII, Division 1 standards did LRQA issue the official Certificate of Compliance/Conformity.

The three Air Receivers were then delivered to the client, accompanied by a complete documentation package including fabrication records, drawings, hydrostatic test reports, and original LRQA certificates.

5. From Domestic Projects to Global Reach

Throughout its development journey, PREBECC has remained steadfast in its philosophy:

“Quality is not a destination – it’s a continuous journey of improvement.”

From its early projects serving the domestic market, PREBECC has established a strong foundation by adopting international fabrication standards such as ASME (USA), EN (Europe), JIS (Japan), and TCVN (Vietnam) in the design and manufacture of Pressure Vessels and related equipment.

Mastering and applying multiple international codes has enabled PREBECC to meet the stringent technical requirements of major local industries – including energy, oil & gas, petrochemical, food processing, and construction materials – while also proving the technical competence of Vietnamese engineers to leading certification bodies such as LRQA, DNV, ABS, and BV.

Building on that foundation, PREBECC has progressively expanded its capabilities, participating in projects with higher standards and tighter tolerances, where every aspect – from design and welding procedures to NDT and hydrostatic testing – is strictly controlled under its international-grade Fabrication Quality Management System.

The successful completion and export of three ASME Section VIII Division 1 (2025 Edition) Air Receivers to the U.S. market marks a significant milestone in this journey. It stands not only as proof of PREBECC’s global-level engineering and manufacturing capabilities, but also as a proud achievement for Vietnam’s mechanical industry – showcasing the rise of a young Vietnamese manufacturer whose products now meet the standards of the very nation that created ASME itself.

From delivering certified equipment for local factories to exporting globally recognized Pressure Vessels, PREBECC continues to affirm the new stature of Vietnamese engineering – confident in integration, mastering technology, and creating value beyond borders.

With the philosophy of “We build your plant”, PREBECC not only builds equipment – but also accompanies customers on the journey to build more efficient, safe and sustainable factories, contributing to bringing Vietnamese technical imprint further on the global industrial map.