In today’s volatile economic climate – marked by rising fuel prices and tightening environmental regulations – energy efficient boilers have become a critical solution for cost optimization. This article highlights the hidden costs of traditional boilers across industries such as food processing, chemicals, and packaging, where outdated systems may be wasting hundreds of millions of VND annually.

We introduce next-generation boiler technologies with 90–95% thermal efficiency, delivering 20-40% fuel savings and payback periods as short as three years.

Beyond tangible savings, energy-efficient boilers also provide intangible benefits – from minimizing legal risks and enhancing a “green” brand image, to unlocking access to green financing. These are long-term strategic investments that support sustainable growth and improve competitiveness.

1. Investing in Energy-efficient boilers: A strategic choice for modern businesses

With rising fuel costs – e.g., coal prices (Grade 5A) up 15-20% in Q1 2024 versus the same period last year (per EVN/Ministry of Industry and Trade reports), many companies have realized that energy efficiency is no longer optional, but essential for maintaining profitability and market position.

In industries from food and textiles to chemicals, packaging, wood, and rubber, steam is indispensable. Yet, many businesses still rely on traditional boilers – unaware that they may be losing hundreds of millions of VND annually.

The “Hidden Costs” of traditional boilers – Industry insights

Many factories struggle with skyrocketing energy bills but hesitate to upgrade to high-efficiency boilers. This reflects a classic opportunity cost – where a modest investment upfront could deliver substantial long-term returns.

Food & Beverage industry

- Steam usage: Accounts for 30–40% of total energy costs in breweries, dairy plants, and beverage factories.

- Example: A mid-sized dairy plant may use 5–10 tons of coal/day or 30–50 m³ of FO oil/month (Data: Ho Chi Minh Energy Conservation Center).

- Fuel cost: With coal at VND 1.8–2.5 million/ton, using 5 tons/day equals VND 12.5 million/day, or ~VND 375 million/month.

- Potential savings: With a 15–20% cut in fuel use, monthly savings could reach VND 56–75 million.

Chemical & Pharmaceutical industry

- Steam demand: High due to distillation, drying, and chemical reactions—often >40% of total production cost (Data: Vietnam Chemical Association).

- Example: A plant consuming 20 tons/month at VND 2.5 million/ton spends ~VND 50 million/month.

- Efficiency upgrade: Switching from a 70% to a 90% efficiency boiler can save ~22% fuel = VND 11 million/month.

Packaging & Paper industry

- Steam usage: 25–35% of total energy use for drying and fiber processing.

- Example: A small paper plant may consume 200–300 tons of coal/month (Data: Vietnam Energy Institute).

- Fuel cost: 250 tons/month at VND 2.5 million/ton = VND 625 million/month.

- Savings potential: A 10–15% efficiency gain could reduce costs by VND 62.5–93.75 million/month.

Labor & Maintenance costs: The hidden burden

Beyond fuel consumption, traditional boilers impose substantial ongoing costs on businesses:

Manual operation costs:

- Older boilers typically require more manpower for monitoring, manual fuel feeding, and frequent adjustments.

- With the average boiler operator earning VND 7–10 million/month, maintaining 2–3 operators per shift can cost VND 14–30 million/month in labor alone.

Maintenance, repairs, and parts replacement:

- Due to lower efficiency, traditional boilers are prone to wear, scaling, leaks, and unexpected breakdowns.

- Regular maintenance tasks – such as descaling, replacing fire tubes, fixing valves or pumps – can cost tens to hundreds of millions of VND annually. These expenses exclude the cost of production downtime during repairs.

Energy-efficient boilers: Not a cost, but a strategic investment

Energy-efficient boilers do more than cut fuel consumption—they optimize your entire steam system:

Lower maintenance and thermal loss: Thanks to durable materials, advanced combustion, and smart control systems

Improved operational efficiency: Stable, high-quality steam reduces downtime and production interruptions

Stronger brand image: Demonstrates environmental responsibility and regulatory compliance—key to attracting sustainability-focused clients and partners

Environmental bonus: Lower CO₂ and pollutant emissions contribute to both corporate and national green growth goals

Investing in energy-efficient boilers isn’t just about cutting costs—it’s a long-term, strategic move that drives profitability, strengthens resilience against rising energy prices, and builds lasting competitive advantage.

2. Energy-efficient boilers vs. Traditional boilers

2.1. Operating cost comparison

Traditional Boilers: Short-term savings, Long-term risks

Traditional boilers – especially those using basic combustion chambers or with poor heat exchange design – typically operate at only 60 – 75% efficiency. This means that 30 – 40% of the fuel’s energy is wasted as heat loss through flue gas, radiation, or inefficient heat transfer.

Example: A 2-ton/hour boiler using diesel oil (DO) priced at VND 20,000/liter consumes roughly 150 liters/hour. At low efficiency, over 1,000 liters of fuel may be wasted every week—equivalent to more than VND 20 million in fuel loss in just 7 days.

Additional hidden costs include:

- Frequent maintenance due to scale buildup, corrosion, and shortened equipment life

- Pressure drops and unstable steam supply affecting production efficiency

- Higher emissions leading to environmental fines and regulatory scrutiny

Energy-efficient boilers: High performance technology

Modern boilers are equipped with advanced combustion and heat recovery systems, such as:

- Circulating fluidized bed (CFB) or Forced circulation combustion chambers

- Exhaust gas heat recovery units (Economizers)

- High-grade thermal insulation to minimize radiant heat loss

These technologies boost thermal efficiency to 90 – 95%, enabling:

- 20–40% fuel savings

- VND 300–800 million in annual cost reduction (depending on boiler size and fuel price)

- Extended lifespan (15–20 years) with corrosion-resistant alloy steel and protective coatings

A medium-sized plant operating a 3-ton/hour boiler reported a 35% cut in fuel costs – saving approximately VND 500 million per year – after upgrading to a high-efficiency system.

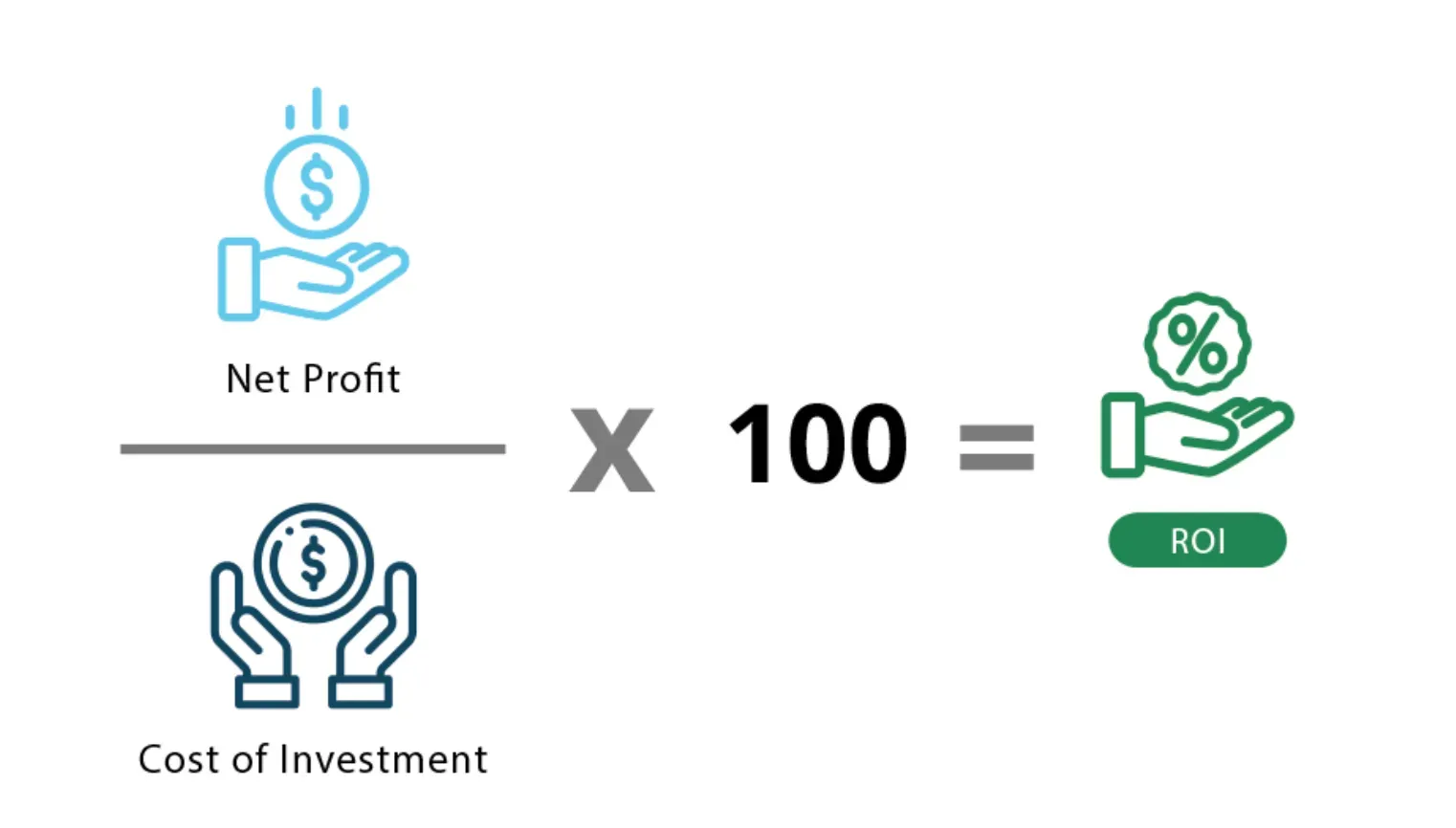

2.2. Calculating ROI for energy-efficient boilers: A holistic approach

When assessing the return on investment (ROI) for an energy-efficient boiler, it’s important to look beyond fuel savings alone. A comprehensive analysis should include both common cost inputs and output benefits.

Key factors to consider in ROI calculation:

a) Initial Investment (CI):

This includes the total upfront cost of purchasing and installing the energy-efficient boiler system, comprising:

- Cost of the boiler and auxiliary equipment (e.g., economizer, water treatment system, automated control system)

- Transportation, installation, and commissioning costs

- Training expenses for operation and maintenance personnel

- Other related costs

Note: Initial investment can vary significantly depending on the boiler’s capacity, technology, and supplier.

b) Annual benefits (AB)

This refers to the total annual savings and added value, including:

Fuel savings (Primary benefit):

Calculated by multiplying the percentage of fuel consumption reduction (e.g. 20–40%) by the annual fuel cost of the old boiler.

Example: If the old boiler consumes VND 3 billion in fuel per year and achieves a 30% reduction, the annual saving is VND 900 million.

Maintenance & repair savings:

New boilers generally have longer lifespans, fewer breakdowns, and lower maintenance costs.

Estimate the reduction in annual maintenance expenses (e.g. 10–20% of the old boiler’s maintenance cost).

Example: If the old boiler’s annual maintenance cost is VND 100 million, a 15% reduction equals VND 15 million saved.

Labor cost savings:

Modern boilers are typically more automated, reducing the need for direct operating personnel.

Example: Reducing one operator could save around VND 100 million per year (including salary, insurance, etc.).

Increased productivity & product quality (Difficult to quantify but real):

Stable, high-quality steam ensures smoother production, fewer defects, and higher output.

Example: A 1% increase in production due to stable steam may result in significant profit gains.

Lower risk of environmental fines and compliance costs:

Avoid potential environmental penalties, which could reach hundreds of millions of VND annually.

2.3. Hidden ROI gains beyond fuel savings

Beyond direct cost savings, investing in energy-efficient boilers delivers significant added value—often overlooked by many businesses:

Reduced legal risks & Compliance costs

High-efficiency boilers are typically designed to integrate or support advanced flue gas treatment systems, helping to reduce pollutant emissions such as CO, NOx, and SOx. This ensures better compliance with environmental regulations issued by Vietnam’s Ministry of Natural Resources and Environment (e.g., QCVN 19:2009/BTNMT, QCVN 05:2013/BTNMT).

Proactively meeting these standards helps companies avoid heavy administrative fines, operational shutdowns, or reputational damage.

Enhanced brand value & Market access

Green positioning: Companies using energy-efficient and eco-friendly technologies are more likely to be recognized as “green enterprises,” strengthening brand credibility and building trust with customers, partners, and the wider community.

Access to global markets: As sustainability and carbon reduction become global trade requirements – especially in industries like textiles, wood processing, seafood, and agriculture – energy-efficient boilers offer a strategic advantage. They support international certifications (e.g., ISO 14001, carbon footprint standards) and help meet sustainable sourcing criteria in demanding markets like the EU and the US.

Access to green finance & Credit incentives

Improved credit ratings: Many financial institutions favor companies with sustainable development strategies and energy-saving equipment, offering them better credit scores and preferential loan terms.

Eligible for support programs: Businesses may qualify for international environmental funds (e.g., Green Climate Fund – GCF) or government-backed clean energy initiatives aimed at promoting industrial energy efficiency.

3. National policies and incentives: Supporting sustainable industrial growth

Vietnam has shown strong commitment to promoting energy efficiency and green energy through clear national policies and action plans. This provides a solid foundation for businesses to confidently invest in energy-efficient boilers.

Law on Economical and Efficient Use of Energy (2010):

This is the country’s key legal framework to promote energy savings across all sectors, including industry. It encourages investment in energy-efficient technologies and sets out penalties for non-compliance.

National Program on Energy Efficiency (VNEEP 3, 2019–2030):

Approved under Decision No. 280/QĐ-TTg, this program sets clear targets:

• By 2025: Reduce national energy consumption by 5–7% compared to the business-as-usual scenario.

• By 2030: Cut energy use by 8–10%.

The program focuses heavily on key industries, including the replacement of outdated equipment with high-efficiency systems—such as modern boilers.

National Green Growth Strategy (2021–2030, vision to 2050):

Decision No. 1658/QĐ-TTg outlines Vietnam’s commitment to green, low-carbon, and sustainable development. Efficient energy use and renewable energy are central pillars—aligning perfectly with investment in energy-saving boiler technology.

Vietnam’s Net Zero Commitment at COP26:

At the 26th UN Climate Change Conference (COP26), Prime Minister Pham Minh Chinh pledged to achieve net-zero emissions by 2050. To meet this goal, reducing industrial emissions—especially by improving boiler efficiency—is critical and urgent.

With strong policy backing at the national level, investing in energy-efficient boilers is not only financially sound, but also a responsible move aligned with Vietnam’s sustainable development goals and international climate commitments.